One of the best things I have done to the 109 is installed a 200TDI engine. It’s gone from being a fuel hungry underpowered old truck to a relatively economical, powerful & useable vehicle. The 200di (fitting the TDI without the turbo) conversion seems to be quite popular at the moment and is a good idea if you just want a little more power and reliability, it’s a simpler job to fit and a lot of the original series parts can be retained such as the radiator and oil bath air filter – however the engine I bought came with all ancillaries, radiator/oil cooler, hoses etc so not to fit everything would have been a waste. I’m glad I kept the turbo and it would now feel underpowered without it – I now think if you are going to the trouble of fitting a new engine you may as well spend a bit more time and fit the full kit.

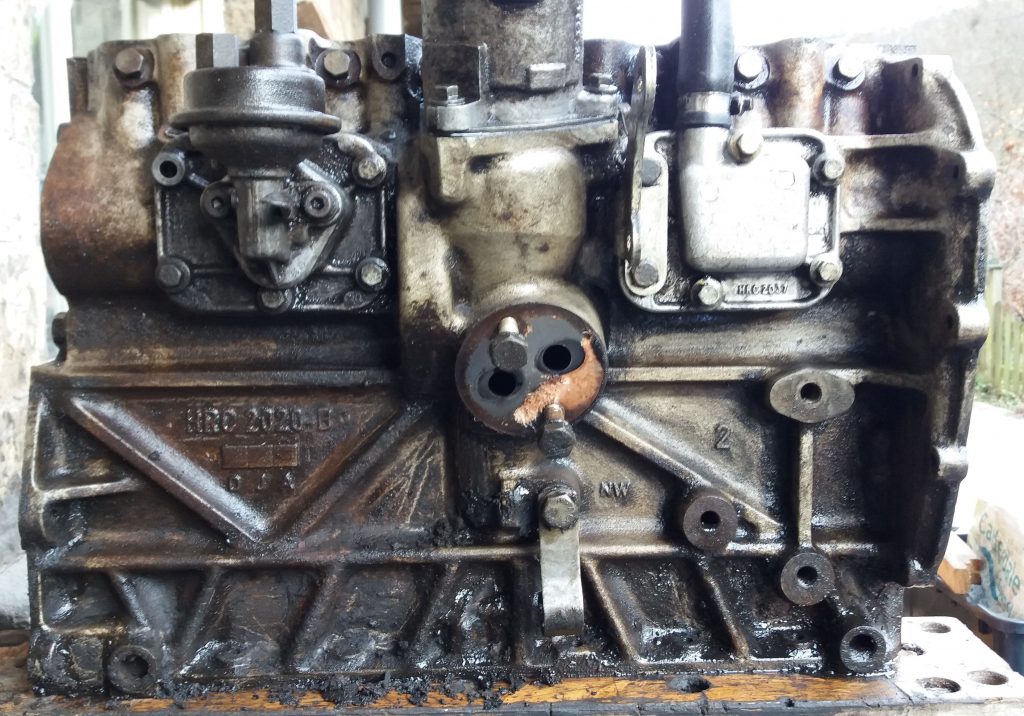

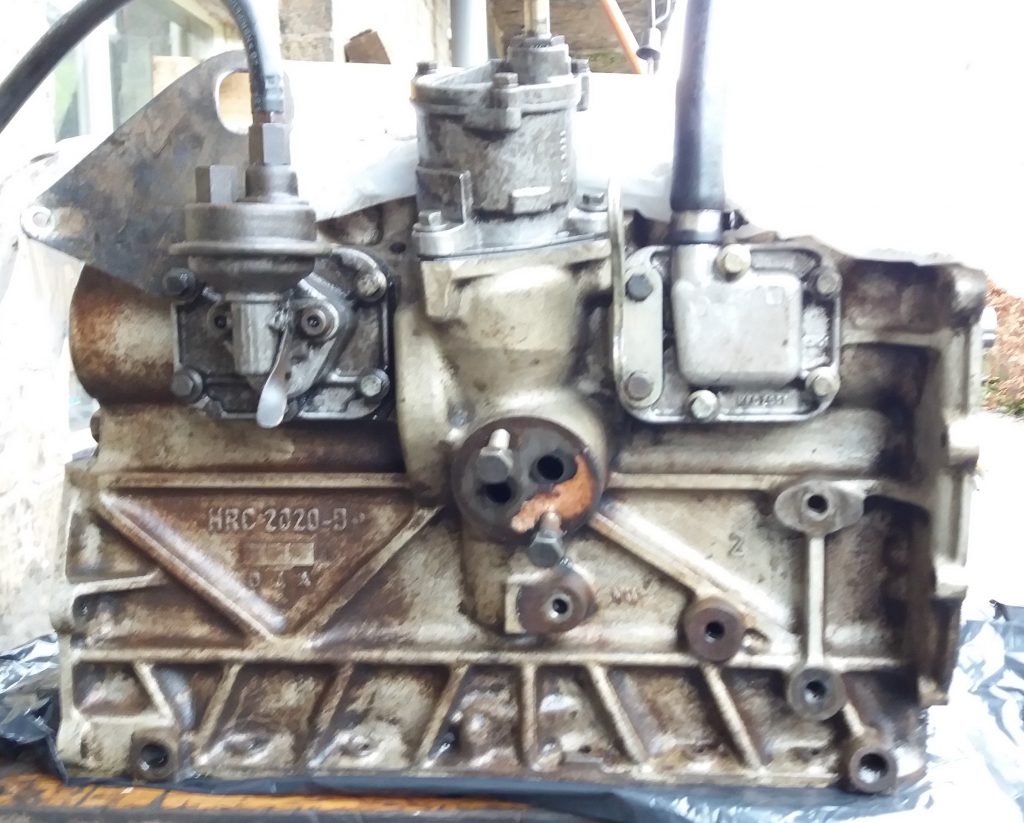

Whereas most people fit discovery engines as they are more common and cost less, I came across a defender engine and gearbox with low miles for the same price as the disco lumps. There are a couple of differences between the two versions – the manifolds are different – the turbo sits low down on the disco engines with injection pump up high but the turbo is high up on the defender engines with the injection pump lower down. It is the shape of the manifolds that give the difference in BHP between the two engines, with the defender variant being slightly less powerful. The timing cases are also different shapes.

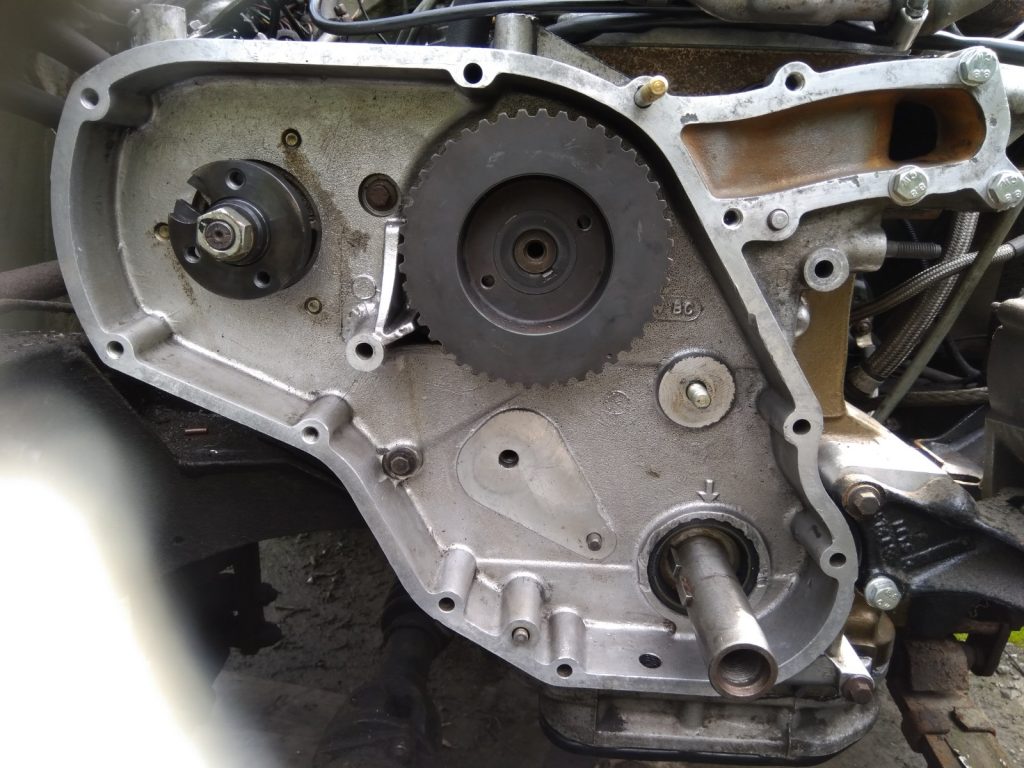

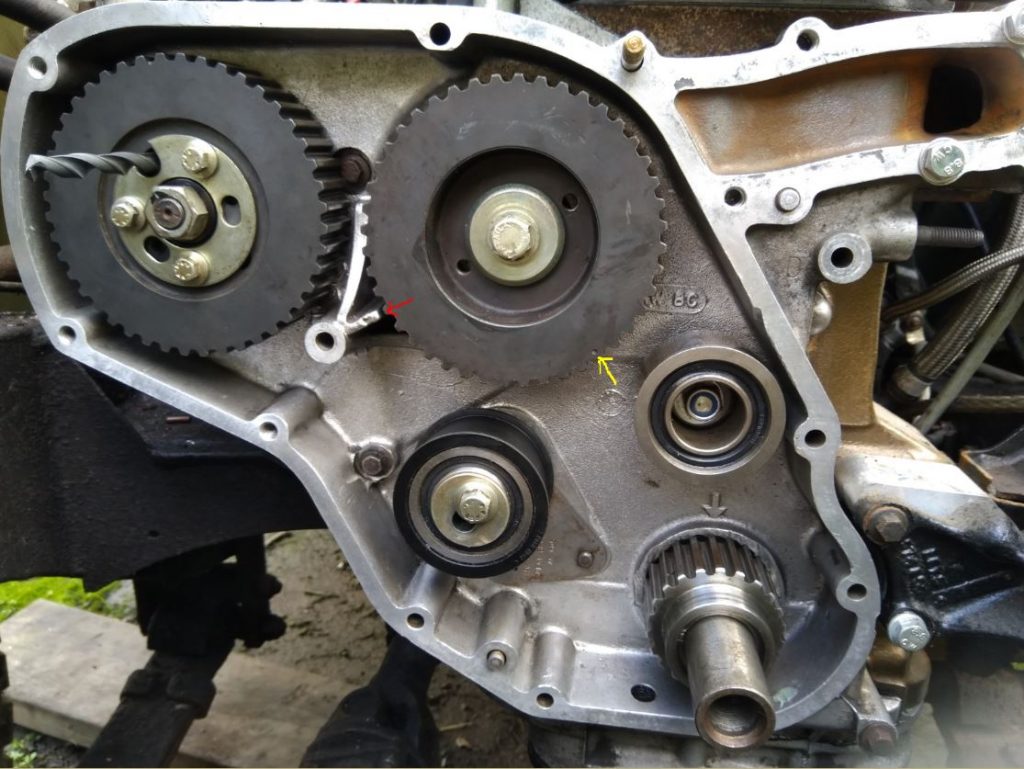

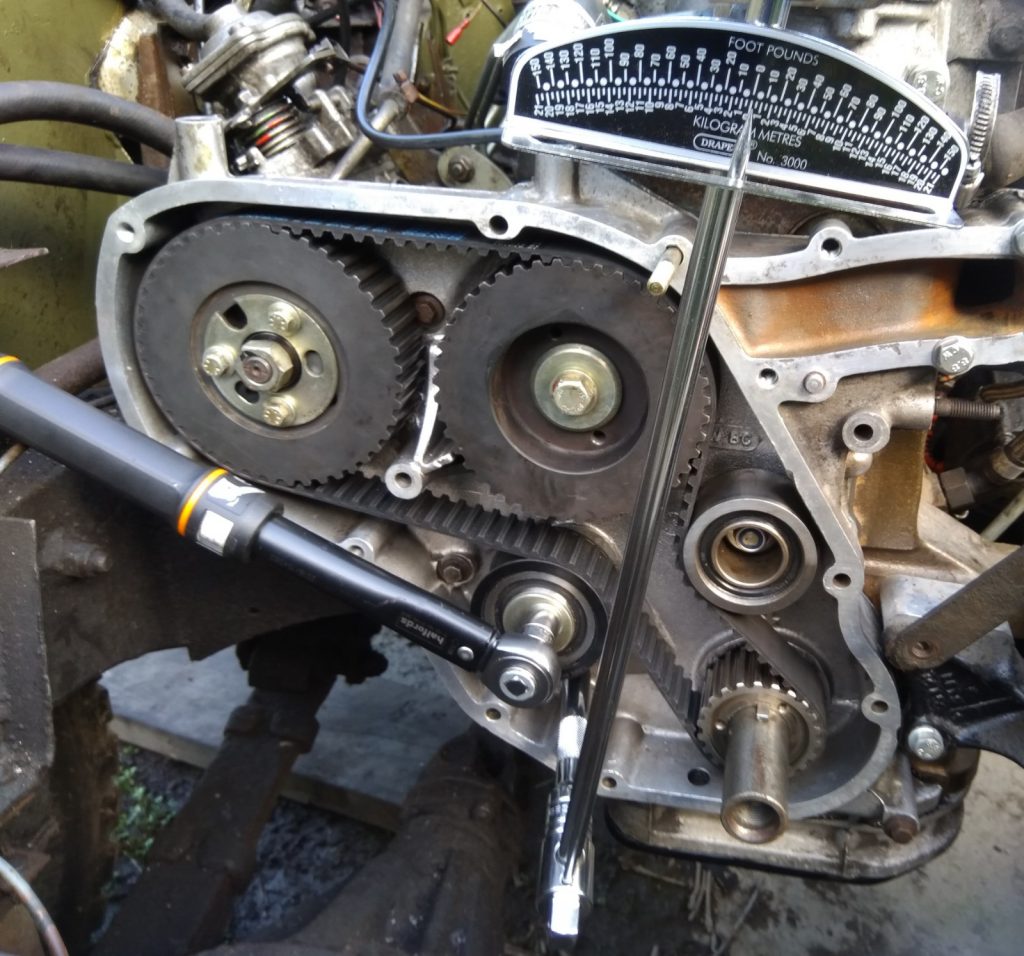

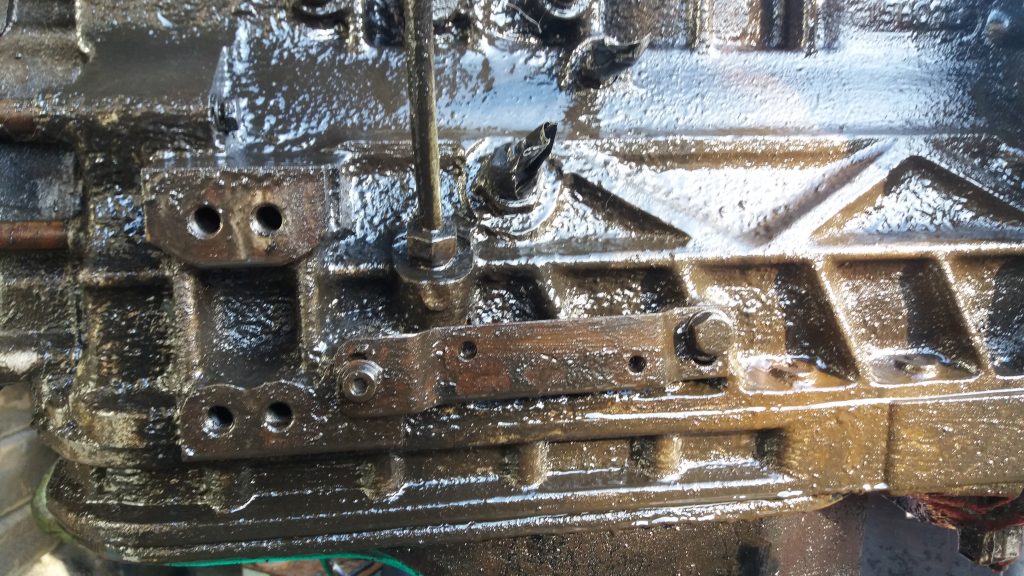

The engine block is the same for both defender and disco versions and you have two choices of position or the right hand engine mount, the disco engine uses the front engine mount bolts and the defender uses the rear bolts which is the same set up as the 12J (2.5D), so the defender engine requires the right hand engine mount moving on the chassis because the the timing case is in the way – the disco engine does not have this problem as the timing case is a different shape so the engine bolts to the standard series chassis engine mount. I decided not to move the engine mount as my chassis is galvanised and I did not want to break the galv, so I decided to swap the defender timing case for a discovery case, the engine was on a stand waiting to go in the vehicle and I had the timing belt to do anyway. It was just a case of removing all the timing gear and fitting the disco timing case in it’s place. I also had to source the disco injection pump bracket as the pump was now sitting much higher, also needed disco injector pipes, all the pulleys had to be changed as the disco ones are different to defenders, disco water pump & disco thermostat housing. I could now bolt the engine straight into the standard series mounts. So now I have what has become a disco engine with defender manifolds! I’ve kept all the defender parts so I can convert it back at a later date.

I wired up the glow plug relay to a switch on the dash, though have I never needed to use them even in -5 temps. I had to relocate the battery as there is no room under the bonnet and I have underseat fuel tanks, I ended up fixing an ammo box between the front dumb irons and the battery has been in there for the last couple of years, however I am going to convert the passenger side fuel tank into a battery box as the tank hasn’t been used for years. I’ll be relocating the battery there in the next few weeks, I’ve already got the tank off to clean up.

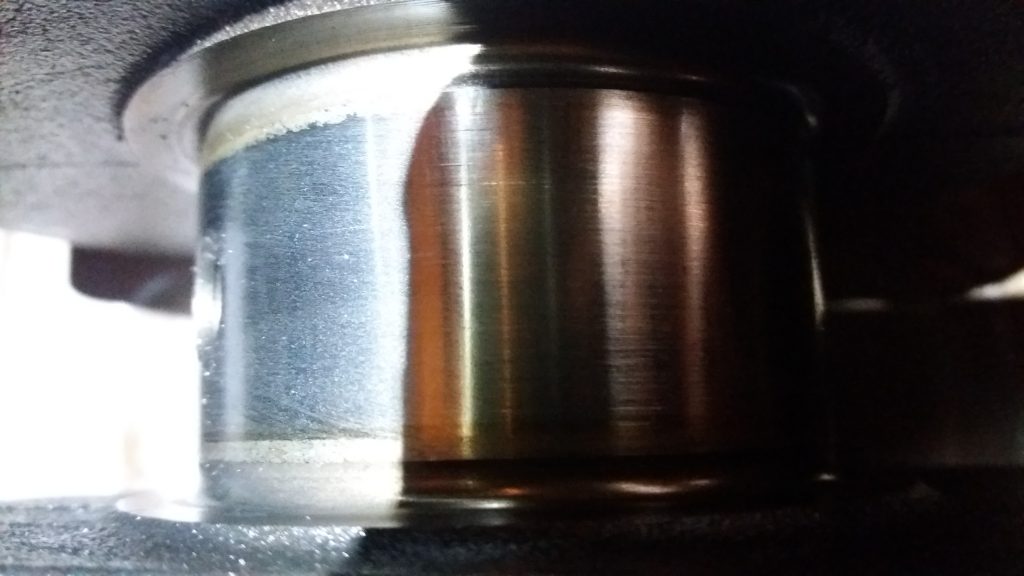

I didn’t do any work to the engine as it was low mileage at 85k, just changed the timing belt and gave it a service before starting it – fired up first time, no smoke! Changed the oil and filters again after a few hundred miles and all has been well since. I’ve had no problems with the gearbox taking the extra power either.