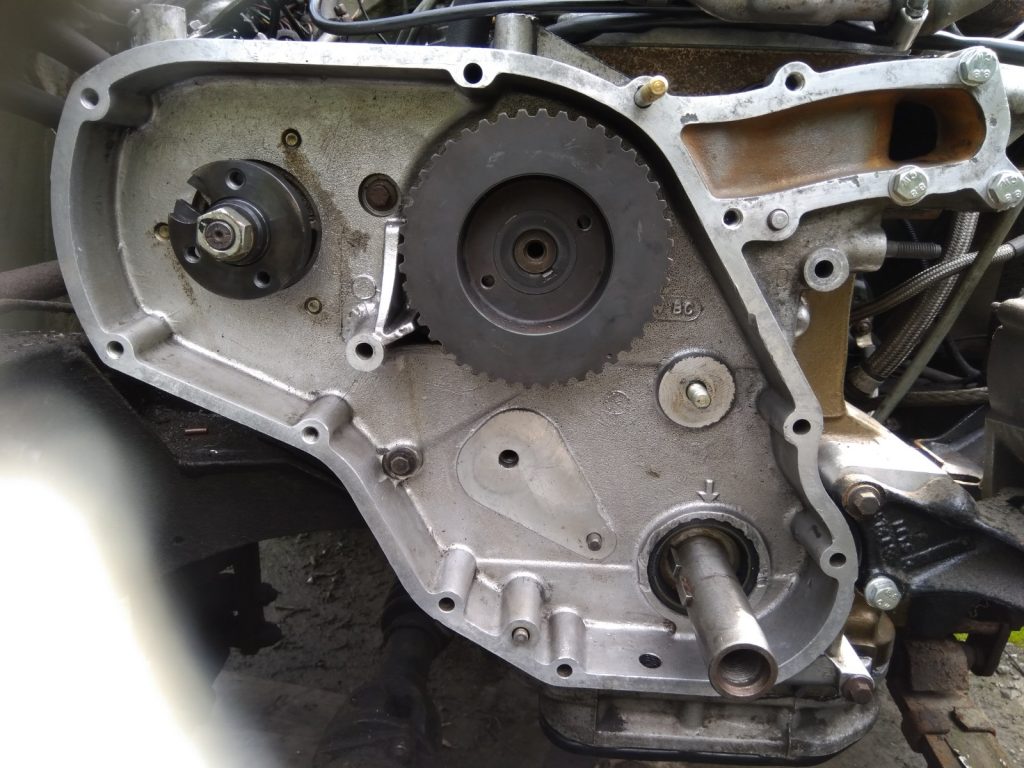

The threads in the block and timing case have now been repaired with Helicoils and the timing case is back on the engine block. Now to replace the timing gear. This is where I’m up to, the cam shaft pulley has already been replaced:

The bolt that secure the pulley onto the camshaft has two O-Rings and these should really be replaced with the timing belt as they stop oil passing down the camshaft into the case.

The cam shaft bolt can be safely undone by resting a large screwdriver against the camshaft timing pointer moulded into the timing cover and jamming it into the camshaft pully to stop it turning as you undo the nut. Torque back up the same way to 45nm.

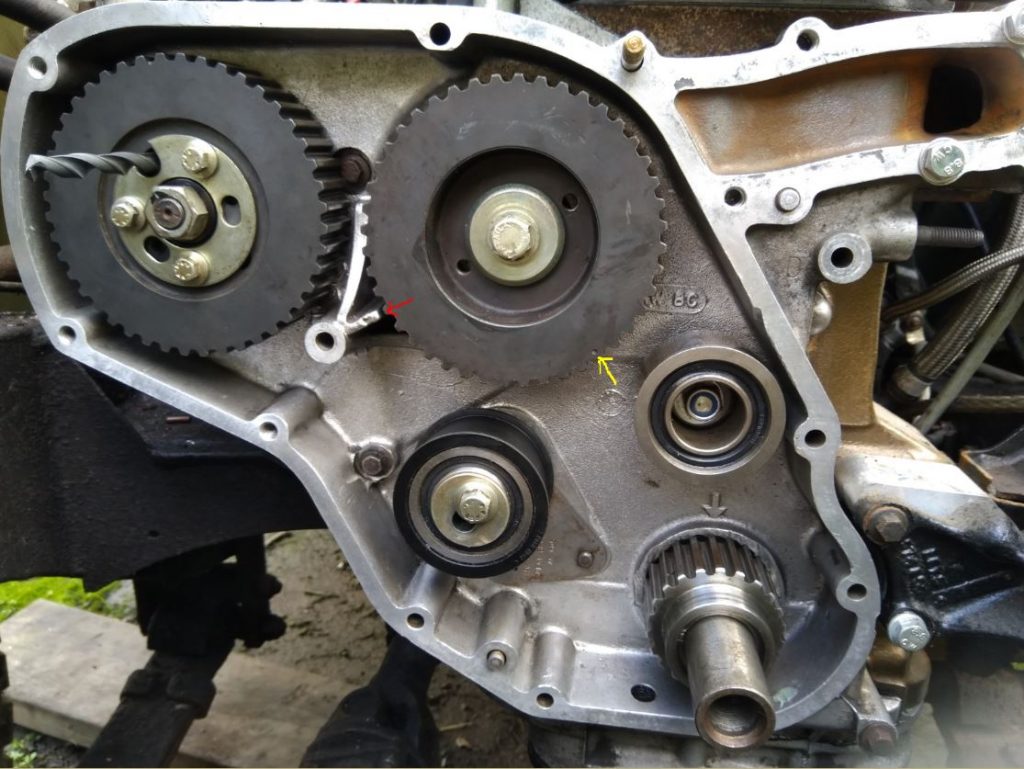

The injection pump is locked with a 9.5mm diameter locking pin (or a drill bit in my case). The pump pulley is secured back on by a flange with three bolts. The holes for the bolts on the flange are slightly elongated to allow for slight movement of the injector pulley in either direction while the injector timing remains locked. This allows the pulley to move slightly as the belt is tensioned. At this stage the bolts should be set finger tight in the centre of the holes and will only be fully tightened once the belt has been correctly tensioned.

Make sure the engine is at TDC before removing the belt. It’s not the end of the world if you don’t, but can be a bit fiddly getting the timing marks to line up afterwards as the camshaft and crankshaft will now be moving independently of each other and you will need to turn them both at roughly the same time to avoid valves hitting pistons etc. In my case I forgot and needed to turn both clockwise to get the timing marks to line up. In the image below you can see the timing dot on the camshaft pulley (yellow arrow) and where is should be (red arrow) lined up with the pointer on the timing case. The crankshaft woodruff key key should line up with the arrow on the timing case. There is also timing mark on the flywheel that you can fit a pin into through a hole in the bottom of the bellhousing to lock the flywheel, however if your 200 is in a Series there is no access to this hole a the cross member blocks it. The timing case marks are accurate enough to fit the belt though, just make sure you haven’t moved the crank when fitting the belt.

The crank and camshafts are now at TDC and the injection pump is locked so the new belt can now be fitted. Fit the idler pulley and torque to 45NM.

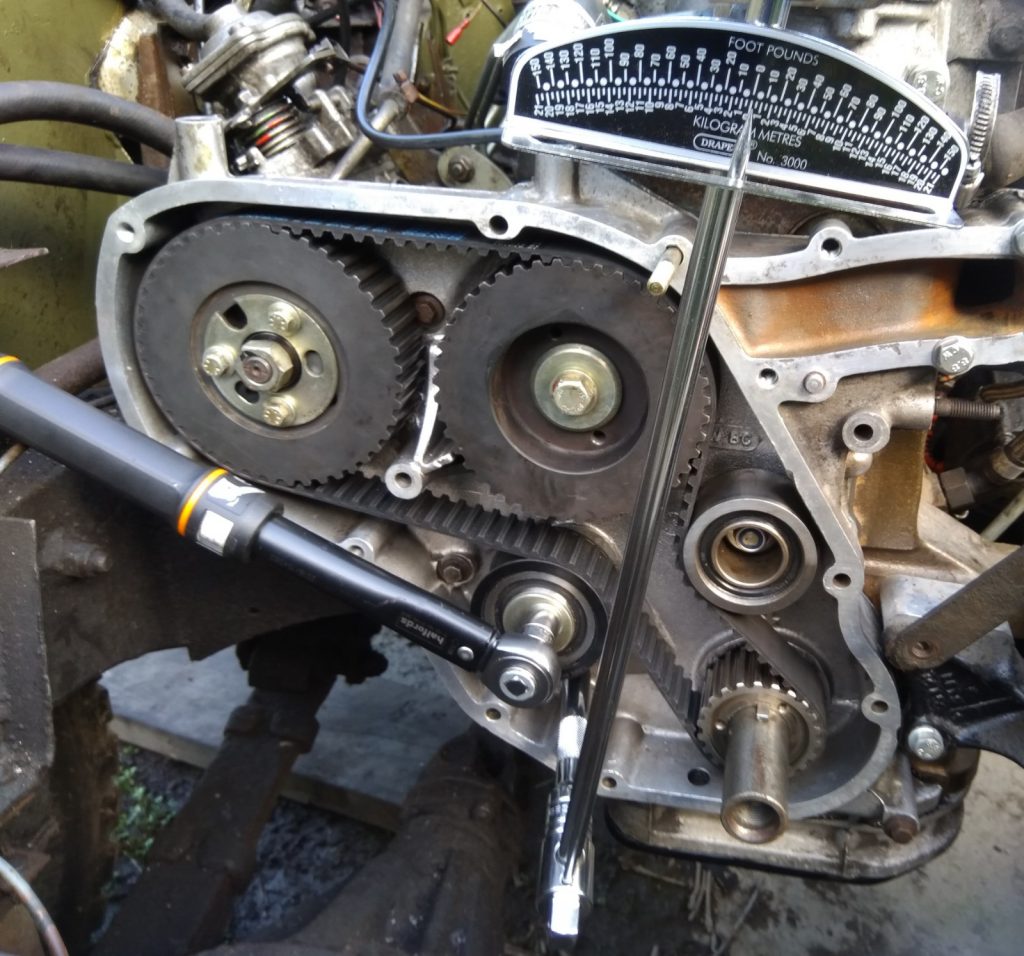

Start by fitting the belt around the crank sprocket, use a piece of folded cardboard between the bottom of the timing case and the bottom of the crank sprocket to hold the belt in place, take it around the camshaft pulley then the injection pump pulley, take care to make sure the pulleys have not moved from their timing marks. Make sure the belt is tight, you may need to slighlty manipulate the pulleys to get the belt to fit correctly. Then fit the tensioner on it’s pivot point on the timing case, using a dial type torque wrench pull it upwards to 19NM for a new belt or 17NM for an old belt. While you are holding the tension fit the tensioner bolt and torque to 45NM.

Now tighten the three injector pump bolts to 25NM and remove the locking pin.

Temporarily refit the crank nut and turn the engine over on the crank nut for two full revolutions back to TDC and check the timing marks are where they should be, the locking pin should be able to fit back in the injection pump (however don’t leave it there!). If you feel any resistance when turning the engine you may be a tooth out on one pulley, so stop and double check the timing marks. If there is no resistance and all the timing marks line up perfectly then you’re all done and can proceed to refit the front cover. The crank nut will require 340nm so make sure you have a suitable torque wrench – I use a very large screwdriver to lock the flywheel against the case through the starter motor hole for this.